Lagom

Meet PARIGNA & ROSHNI

Story & Highlights

Sign up today to our newsletter and get a 10% discount code for your first purchase (excluding art and large custom items).

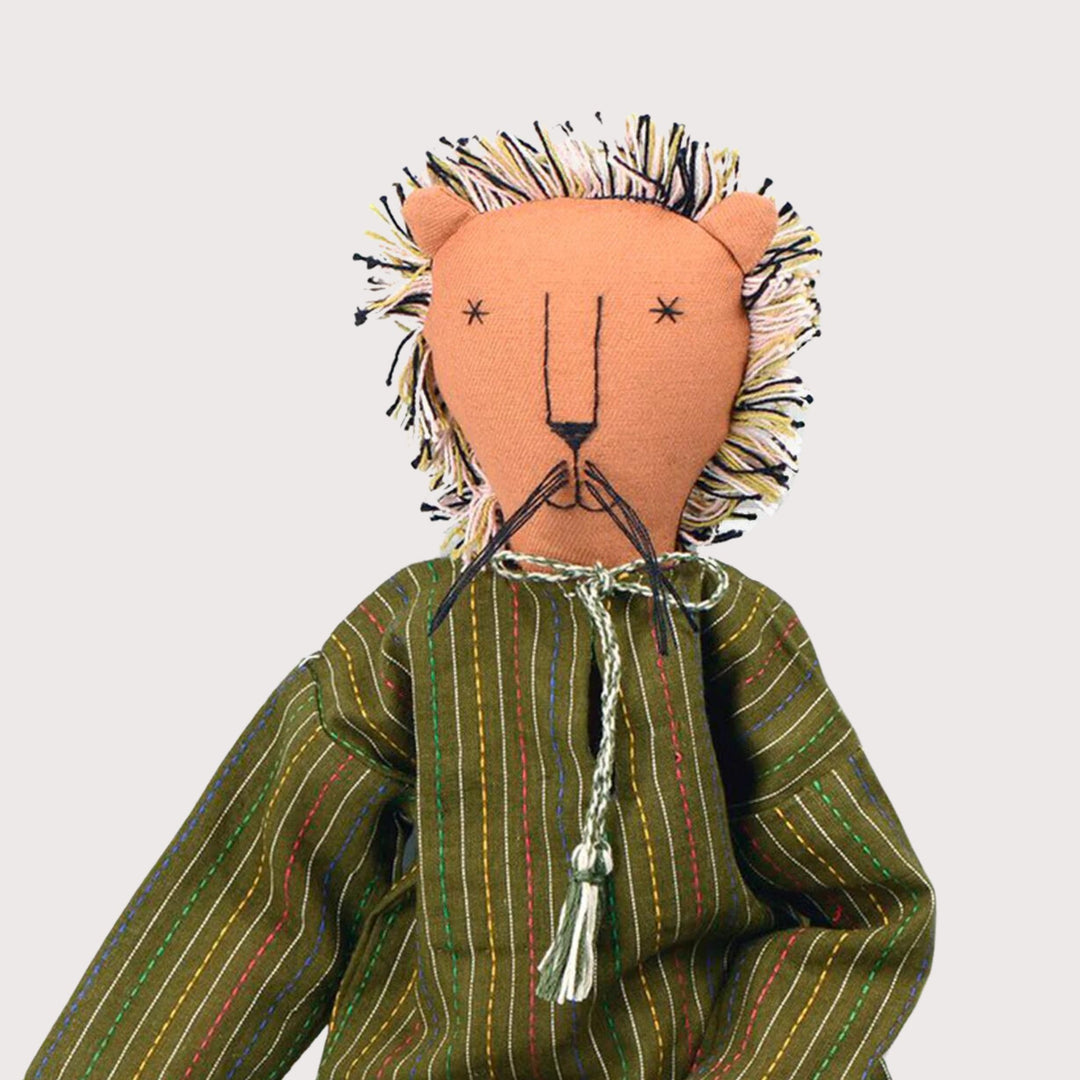

Lagom produces sustainable pyjamas from lotus and rose fabric. Founded by Parigna and Roshini, Lagom continues an old tradition from South East Asian countries where natural waste is turned into soft and breathable fabrics. Based in Mumbai, the brand focuses on small batch production to reduce waste and promote thoughtful consumption.

Coming from different design disciplines, Parigna and Roshini collaborate to explore the fusion of digital and tactile elements. Their shared goal is to create meaningful products by pushing boundaries in material innovation and system design. The curiosity of Lagom's founders drives them to work across various mediums, unbound by industry constraints.

FOUNDERS: Parigna and Roshini

TEAM: 2 Founders

LOCATION: Mumbai, India

MATERIALS: Rose fabric, lotus fabric, BCI cotton

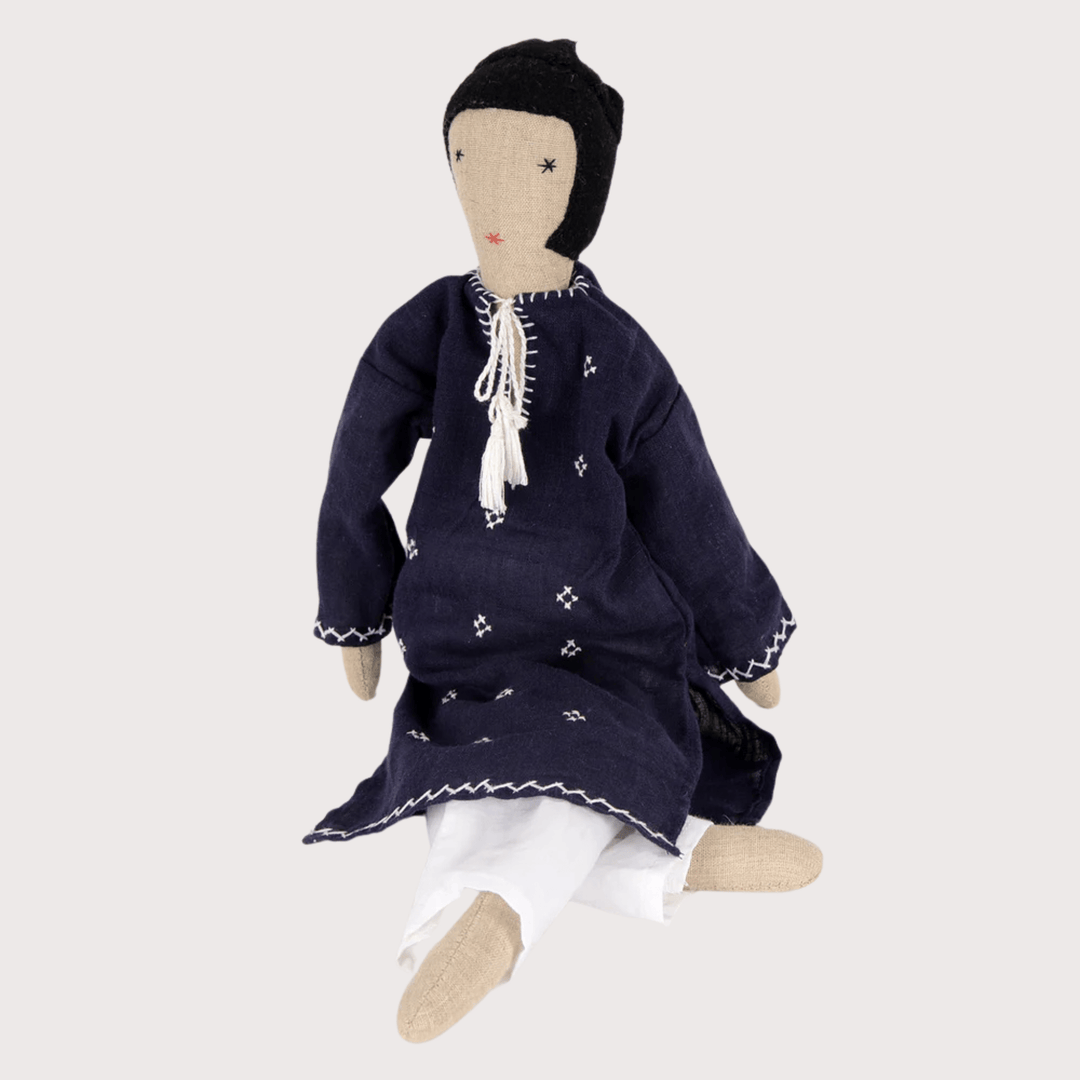

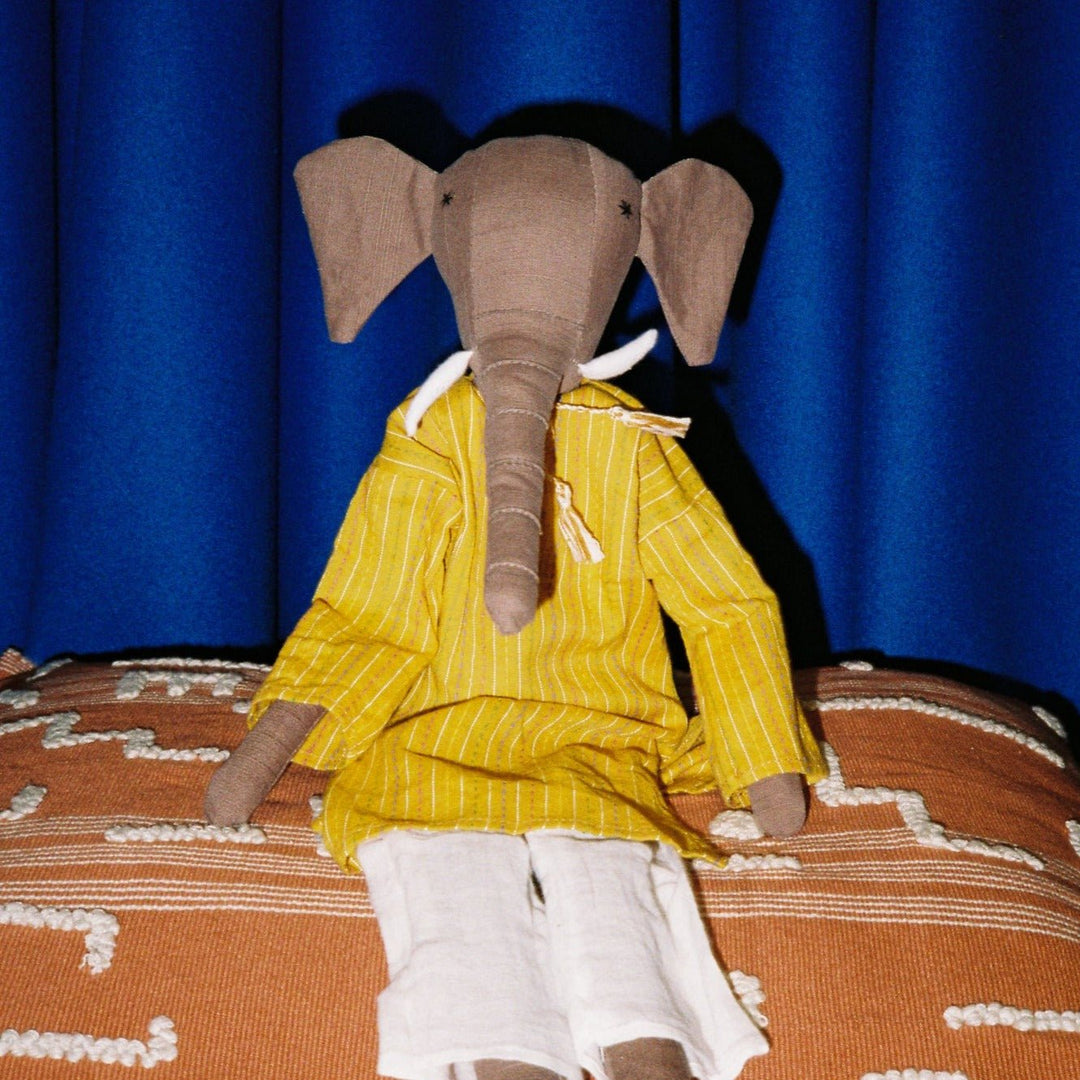

Lagom's products are thoughtfully designed to enhance the flow of the fabrics, allow the pieces to adapt to the wearer's various roles throughout the day. They are intended to become the go-to garments for individuals. The pieces are versatile, ready to be worn in any context, and are designed to make you feel at ease and at home.

One of Lagom's core raw material is the rose petal fiber, a remarkable cellulose fiber, which is derived from the byproduct of rose petals and rose bushes. Through a meticulous extraction and processing method, this fiber undergoes transformation into a glossy and plush spinning material that closely resembles silk. Its qualities are truly outstanding - it boasts a lightweight nature, excellent breathability, and is particularly well-suited for wear in hot and humid conditions. This innovative use of natural waste showcases a commitment to sustainable practices and an appreciation for the beauty that can be found in repurposed materials.